Comparing Modules: Batch Procedure vs. Settings & Changeover

Comparing Modules: Batch Procedure vs. Settings & Changeover

Each module benefits specific use cases — what’s the right fit for your manufacturing operation?

What sets the Sepasoft Batch Procedure Module apart from the Sepasoft Settings and Changeover Module? At first glance, they may appear rather similar.

Both aim to simplify the management of manufacturing processes. Both leverage the Ignition platform for real-time monitoring and analysis. And both use “recipes” — although each module defines the term differently. That’s because they are designed with distinct functionalities for distinct purposes and use cases.

This post will take a high-level look at their key features to help you determine which module is best suited to meet the specific needs of your business.

- Introducing the Batch Procedure Module

- Examining the Settings & Changeover Module

- Contrasting Batch Procedure and Settings & Changeover

1. Introducing the Batch Procedure Module

Two main groups of use cases benefit from this particular module: (1) ISA-88-aligned batch management and (2) procedural workflow control.

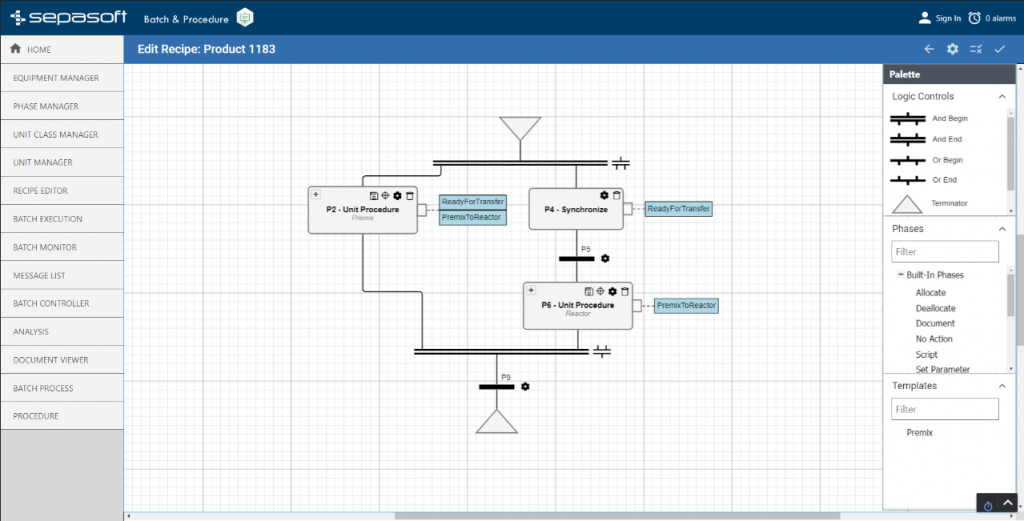

The Batch Procedure module uses a workflow engine informed by the ISA-88 standard. At the same time, it’s flexible enough to accommodate workflows beyond typical batching. This means you can use the module to manage a wide range of processes, including manual, machine-controlled, and other types of manufacturing processes.

How it Defines ‘Recipe’

The concept of recipes is at the heart of the Batch Procedure Module. Recipes are used to capture the process actions and logic necessary to carry out a manufacturing process. Consequently, it provides a standardized way to describe the sequence of process operations, equipment and materials required, and the order in which each step should be performed. By using recipes, you can ensure your manufacturing processes are repeatable, consistent, and efficient.

Key features of this module include:

- Graphical Recipe Editor: Allows for easy editing of recipes on a user-friendly screen using modern drag-and-drop technology.

- Separation of Recipes and Equipment Control: Empowers Recipe Authors and Control Systems Engineers to specialize in their independent roles.

- Real-Time Batch Status Visibility: Allows operators to easily check the status of a batch without an SFC (PFC) chart.

- Electronic Batch Records: Provides detailed batch information and simplifies recordkeeping.

- Built-In User Defined Type (UDT) Interface: Streamlines configuration and minimizes errors.

- Dynamic Dashboards: Features real-time custom dashboards tailored to the needs of the company.

- Track & Trace Integration: Enables material tracking within workflows.

- E-Signature and other user-in-the-loop features: Make for user-friendly and accessible management

2. Examining the Settings and Changeover Module

The Settings & Changeover module was designed to simplify the process of managing set points for PLC-driven manufacturing processes. Set-points are collections of settings that are needed within the PLC to control plant floor machines to make a specific product. Traditionally, PLCs held both the logic necessary to control equipment and the set-point collections relevant to specific products.

However, Settings and Changeover allows set-point collections to be stored in a SQL database and administered through Ignition with Settings & Changeover components and features, making set-point management more efficient and effective.

Key features of this module include:

- SQL-Based Set-Point Management: Compared to proprietary PLC-based set-point management, this module brings enhanced flexibility and scalability. As a result, you can better manage your set points, reducing the time and effort required to make changes and updates.

- Set-Point Inheritance: Set-points can be grouped into families and subfamilies, making the process easy to manage even when sets grow large. This feature allows you to quickly identify and address any issues, which, in turn, contributes to minimizing downtime and the risk of errors.

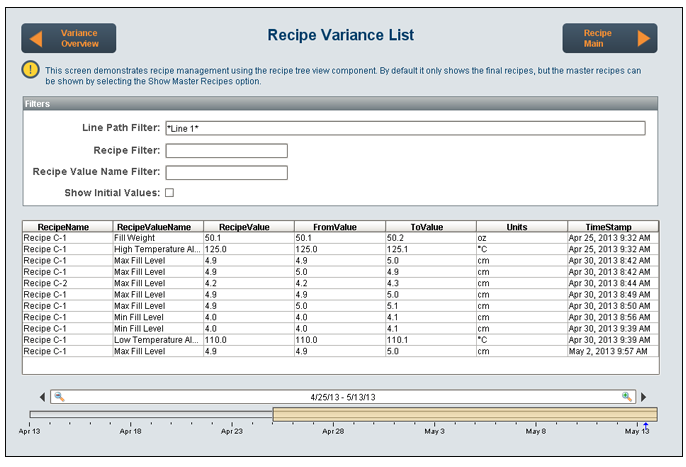

- Set-Point Variance Monitoring: With real-time monitoring of set-point values, you can swiftly detect any deviations or changes that may indicate a problem with the manufacturing process. By rectifying issues at an early stage, you reduce the risk of product defects and minimize waste.

- Set-Point Reporting: The set-point reporting feature provides detailed information on set-point values and their associated parameters, enabling you to examine trends and patterns that can inform manufacturing optimization. The end result is a decrease in costs, improved quality, and increased overall efficiency.

3. Contrasting Batch Procedure and Settings and Changeover

Sepasoft’s Batch Procedure and Settings and Changeover modules both aim to optimize manufacturing processes driven by programmable logic controllers (PLCs). But the overlap in features does not change the fact they serve different purposes, targeting different problem sets and use cases. Let’s look at the key differences:

Sharing Settings with PLCs

The Batch Procedure Module comes with a built-in Equipment Phase that has standard ISA-88 control values, making it easy to share dozens of data points with PLCs. However, Settings and Changeover is designed to share hundreds or even thousands of data points with PLCs, a feature that’s useful to businesses with larger and more complex manufacturing processes.

Recipes

While both products use the term “recipe,” each context brings a different meaning. In Batch Procedure, a recipe represents relevant settings as well as the logical workflow required to execute a process. In contrast, Settings and Changeover uses a recipe to indicate a collection of set points, which have no logic for process control. This difference in the use of recipes reflects the different purposes of the two products.

Feature Depth

Batch Procedure represents a feature-rich batching and workflow engine with integrations for user documentation, electronic signatures, material traceability, and much more. It is the heart of Sepasoft’s MES offering and represents a very powerful toolset. In comparison, Settings and Changeover has a more modest target feature set around managing settings only. While both solutions aim to optimize manufacturing processes driven by programmable logic controllers, they have different levels of depth and should not be viewed as interchangeable.

Use Cases

Each module benefits certain use cases. The Batch Procedure Module is suitable for businesses that need to manage batch processes, manufacturing procedure-driven workflows, and hybrid processes in one toolset. In sum, use cases include:

- Batch Manufacturing

- Hybrid Processes

- Workflow Control

- Quality Control

On the other hand, Settings & Changeover is designed to simplify the process of managing set points for PLC-driven manufacturing processes. It is a good match for businesses that need to manage set points for their manufacturing processes and want a flexible and scalable solution that is easy to use and provides real-time monitoring and reporting capabilities. It works well in environments, such as:

- Continuous Manufacturing

- Multi-Product Manufacturing

- Process Changeover

Questions?

Which module is the most optimal fit for your manufacturing operation? We can assess your variables and determine the next steps. Contact us to start a conversation.