Empower Your Production Staff with an Intuitive Batch Processing Solution

Batch Manufacturing Made Simple

Golden Batch Comparison

Analyze high-quality data to determine the optimal recipe.

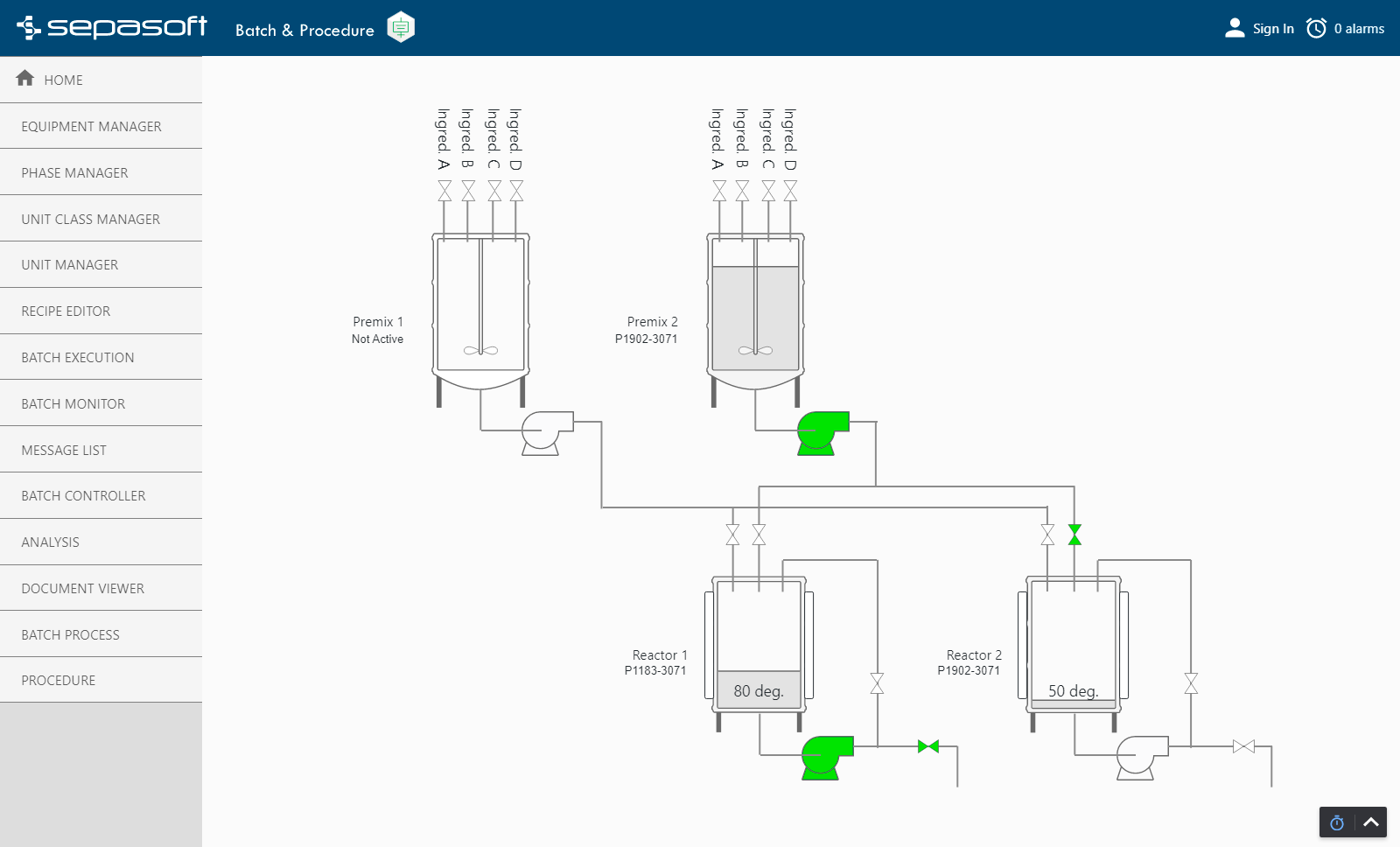

Real-Time Batch Status

Easily monitor the status of a batch without an SFC (PFC) Chart.

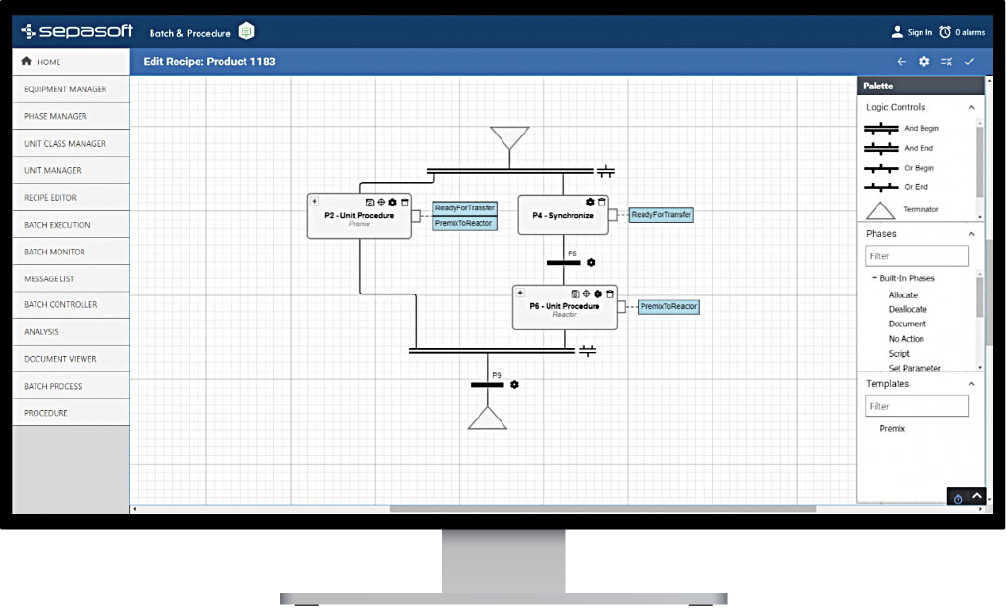

Graphical Recipe Editor

Simply edit recipes on one user-friendly screen using modern drag-and-drop technology.

Separation of Recipes & Equipment Control

Empower Recipe Authors and Control Systems Engineers to specialize in their independent roles.

Unlimited Units Per

Site License

Roll out a batch implementation across your entire site without significant licensing costs or hidden fees.

SCADA/HMI

Integration

Save hours of customization by managing MES, SCADA, HMI, and more, on a single platform.

Excited to learn more? Reach out to us and schedule your live demo today!

Introducing an Updated Modern Interface

The Batch Graphical Recipe Editor functionality includes a low-code, drag-and-drop interface. Simply edit recipes on one user-friendly screen requiring less system training and development labor.

In a production process that fully employs the Sepasoft® MES Suite of modules, starting an individual batch initiates overall equipment effectiveness (OEE) tracking, collects statistical process control (SPC) samples, and provides complete production traceability. All MES data is available for further analysis in one unified system.

Reach out to us to learn more and schedule your live demo today!