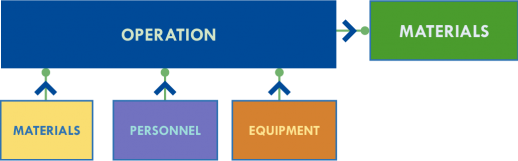

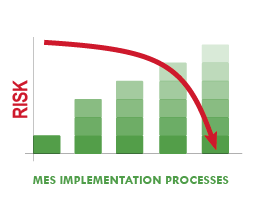

The ISA-95 standard developed by the International Society of Automation (ISA) is a model vetted by many companies across manufacturing sectors. It uses common terminology for describing functions, activities, and departments within the enterprise that MES, ERP, APS, and other systems understand. By following ISA-95, failures can be avoided and cost can be controlled. Because the Sepasoft MES modules are ISA-95 compliant and built from the ground up using the ISA-95 model, understanding ISA-95 concepts are very important before starting your MES implementation. The Sepasoft Quick Start Program will help reduce your risk by lowering the ISA-95 learning curve.