How to Improve OEE

So, you installed OEE. Here’s what should happen next

To get the most out of your new software, follow these 5 actionable steps

Reducing operating costs while increasing asset utilization and operating efficiency— isn’t that what every manufacturer wants to boost profitability? Most of you are well acquainted with the importance of tracking overall equipment effectiveness (OEE) and downtime.

Organizations like Samtec, SugarCreek, Stone Brewing, and Hunter Industries represent a wide range of products, yet they all successfully leverage OEE Downtime. All companies with a manufacturing footprint, whether a food-industry leader (SugarCreek) or an irrigation product maker (Hunter), benefit from bringing visibility to their constraints to help determine the most important areas for improvement.

However, as these companies can likely also attest, software alone cannot change a workflow, fix a chronic machine fault, train an operator, or reduce rework and waste.

To get the most out of your OEE investment, you need to know how to actually use the data to drive change. So, once you have purchased and installed OEE software (congratulations, by the way!) —now what? In this post, we’ll take you through a list of five actionable steps that should follow an OEE installation.

- Maintain a commitment to continuous improvement

- Review dashboards with different personnel

- Review items that keep getting pushed

- Keep track of your wins

- Ask about what is next

5 actionable steps to drive change with OEE software

1. Maintain a commitment to continuous improvement

Not everyone is immediately open to change but it’s critical to stay the course.

It’s not uncommon for feathers to get ruffled when data systems show clearly (especially in a multi-plant environment) downtime, runtime, production rates, and production counts. Politics can get involved at this point as old assumptions are contradicted with accurate, live data.

A commitment to the process of bettering operations and other informing decision areas with data is required. The leadership team will need to assure everyone involved that the point is not to single out anyone for criticism, but to use the new insights to introduce process improvements for the good of the company. Stay the course!

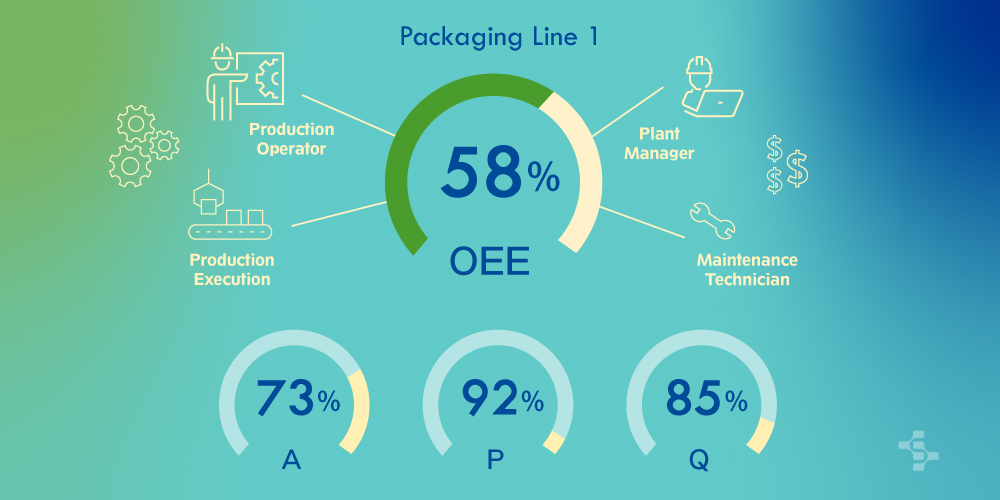

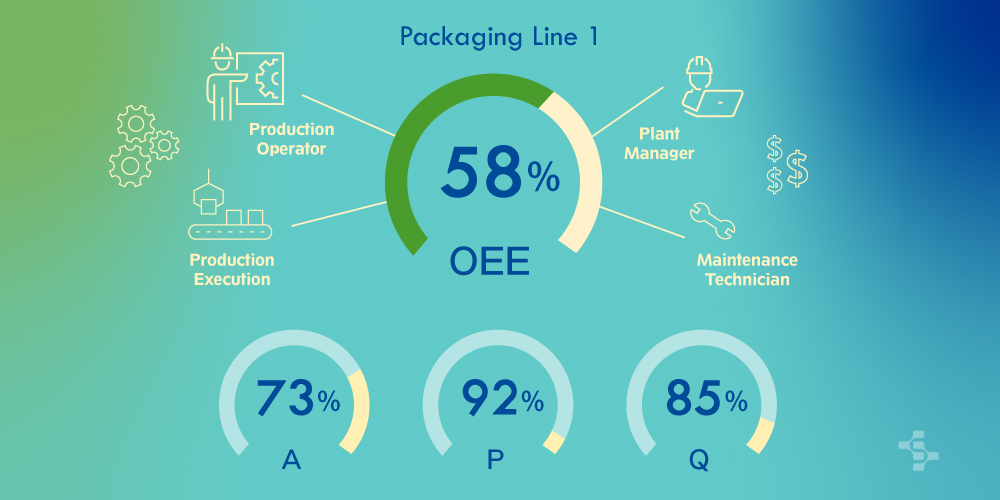

2. Review dashboards with different personnel

Not even the most sophisticated systems can be used to their fullest extent unless all stakeholders have access to the data they need. Check in with each person to ensure everyone is on track.

- Does the Plant Manager see the right info?

- Does the Shift Lead see what they need?

- Does the Quality Manager have the right stuff?

- Do the Operators have the right screens?

- Do Maintenance Techs get the data to make a difference?

Ensure system adoption is happening with different departments and different types of users by ensuring they have relevant data to assist them in their role.

3. Review items that keep getting pushed

Are there initiatives that keep getting kicked down the road, week after week? Continuous improvement includes identifying which items tend to fall off the list of priorities and reintroducing them into the workflow.

Create a punch list for the items that require more than one week to complete. Provide a timeline with a due date per item and a follow-up meeting date to ensure longer-term improvements are completed.

4. Keep track of your wins

Benchmarking will serve you well as you track progress and measure the success of the new product. Think of it this way—you can only improve what can be measured and monitored. A solitary OEE statistic lacks context until it is compared to other production runs over time.

Capture a snapshot of production health right when the system is rolled out. This can serve as a benchmark for productivity gains through the continuous improvement process.

Major milestones should be recorded to help center the team in reality, so that today’s numbers are not the sole focus of the team. Remembering where you have been, and what you have accomplished can help motivate you to take on new challenges.

5. Ask about what is next

The day-to-day users know the process and product better than anyone else. Their input is invaluable to additional optimizations.

Users and stakeholders should be polled periodically (annually or every six months, for instance) to see what they would like to add, change, or enhance in the system to make their lives easier, the software better, etc. By engaging with users, and improving their experience with the system, trust is gained and greater efficiency is unlocked in their work.

How Can Sepasoft Help You?

Do you have questions for us about the Sepasoft OEE Downtime module, the OEE implementation process, or how to use your newfound insights to bring about the change you are looking for? Contact us today. We always want to hear from you.

Read more:

14 steps to a successful MES implementation

MES vs. ERP: Part 1

Weighing the benefits of Sepasoft vs. custom approach