API-Driven Manufacturing: Connecting MES to External Systems

API-DRIVEN MANUFACTURING:

CONNECTING MES TO EXTERNAL SYSTEMS

How do I connect my manufacturing operation to external systems? At Sepasoft, we have received that question more than once. In fact, it’s so common that hardly a call with a prospect goes by without a discussion of this important topic.

Any modern manufacturing operation relies on a number of systems to manage materials, shipments, money, people, and more. In an ideal scenario, all systems communicate with one another. Data flows freely and logically between all levels of the organization, from the top where Enterprise Resource Planning (ERP) systems handle big-picture items like order receiving, raw material purchases, and production orders, to the nitty-gritty of the plant floor.

In between, the Manufacturing Execution System (MES) controls, tracks, and documents the transformation of raw materials into finished goods in real-time. And, just below, Supervisory Control and Data Acquisition (SCADA) and Human Machine Interfacing (HMI) systems handle, respectively, the control of industrial processes and machinery.

In a perfect world, all these systems would talk to one another and share information seamlessly.

Data Islands Cause Issues Throughout Operation

Reality, though, tends to be more complicated, especially when legacy systems and newer technology operate side by side. This can quickly turn into a story of disconnects or “islands of data” as customers often describe it. To keep up with industry trends and changing business demands, organizations often bolt-on systems. Over time, not all pieces of the growing puzzle communicate, making the exchange of information more challenging. To compound issues, reports may be exported to various file types, converted, and imported manually into other systems.

Just imagine a few of the scenarios where business requirements drive the need to connect to external systems:

- Order alignment: To fulfill the next production order, raw materials may need to be ordered down to the line.

- Machine maintenance: During a production run, maintenance on a machine may be required, prompting communication with a computerized maintenance management system (CMMS).

- Production tracking: Post-production results may be required to be input into an ERP system.

- Data retrieval: Higher-level systems may need information from SCADA and MES layer systems, but do not know when to retrieve that data.

- Other scenarios: Line downtime events, production starts, and stops, product quality measurements

The Benefits of API-Driven Communication

Application Programming Interfaces (APIs) provide flexible mechanisms to exchange information between systems and increase efficiencies in the plant. In other words, an API defines how two applications will communicate with each other and what data will be passed and received.

In each of the above examples, you could benefit from an API call to an external system based on an event trigger. Using event-driven API communication improves synchronization across software systems and reduces incorrect or duplicate data.

In a manufacturing environment, the use of Web Service APIs allows for real-world events to trigger communication with external systems. This reduces data islands in the plant while opening the door to talented employees who can leverage the vast amount of data owned by the organization.

In sum, some of the wide range of benefits include:

Access to up-to-date, accurate information: When APIs bring together disparate systems, enabling the sharing of information, the leadership team can make assessments and decisions based on real-time data.

More innovation: Data exposed via API can also be a source of innovation by providing easier access to a broader audience within the organization.

Efficient communication: When all parts of the organization receive accurate and meaningful information, issues can be instantly addressed before they cascade down the line. That saves time and money.

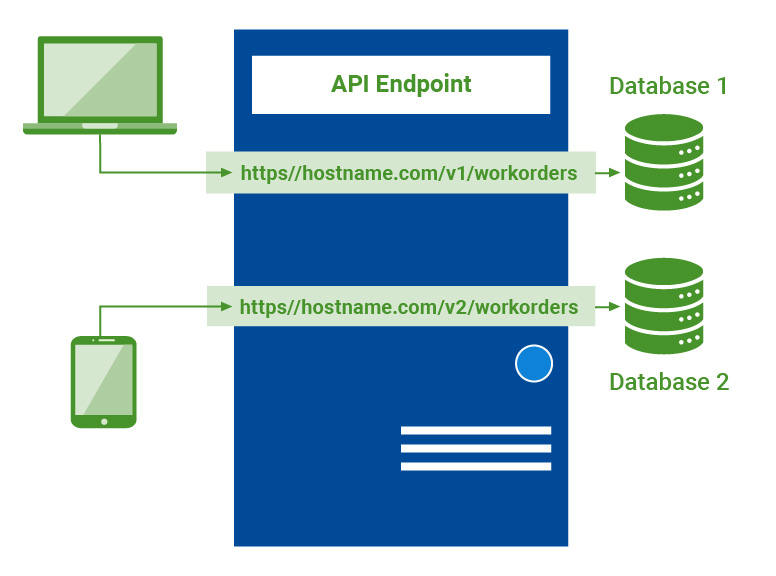

Development of generic data extraction points: The power of Web Service APIs stems from their ability to abstract data sources from the requesting source. This provides flexibility to develop generic data extraction endpoints. The layer of abstraction also provides the ability to modify data source structure. For example, if an API becomes the “gatekeeper” for the database, the structure of the database may change without affecting existing applications. This abstraction can also provide the flexibility to modify the data source entirely, such as a change in ERP vendor.

Development of generic data extraction points: The power of Web Service APIs stems from their ability to abstract data sources from the requesting source. This provides flexibility to develop generic data extraction endpoints. The layer of abstraction also provides the ability to modify data source structure. For example, if an API becomes the “gatekeeper” for the database, the structure of the database may change without affecting existing applications. This abstraction can also provide the flexibility to modify the data source entirely, such as a change in ERP vendor.

How can Sepasoft help?

To learn more about connecting your MES to external systems and the use of APIs, please contact Sepasoft! We are here to answer any questions you may have and provide helpful guidance for your project.

Read more

MES vs. ERP | Part 3

MES vs. ERP | Part 2

MES vs. ERP | Part 1