WHAT IS MES?

What Is a Manufacturing Execution System (MES)?

Manufacturing Execution System (MES) is software that manages, tracks, and documents the real-time execution of manufacturing processes. It connects business-level planning systems, like ERP, with the equipment and personnel on the shop floor—ensuring that production runs as intended, every step of the way.

By coordinating orders, enforcing quality standards, guiding manual tasks, and capturing detailed records, MES helps manufacturers reduce errors, improve throughput, and respond quickly to change.

Why MES Matters

Manufacturing companies manage a wide range of resources—materials, shipments, finances, personnel, and more. To stay competitive and operational, they rely on systems that span the entire organization, from enterprise-level functions like finance and sales to activities on the plant floor, where the actual work gets done.

On the shop floor, systems take many forms: software applications, spreadsheets, handwritten notes, verbal instructions, or even the expertise of a seasoned employee. Regardless of the format, some form of coordination must exist. Without it, manufacturers risk missed shipments, poor quality, compliance issues, or even complete production failure.

Where MES Fits

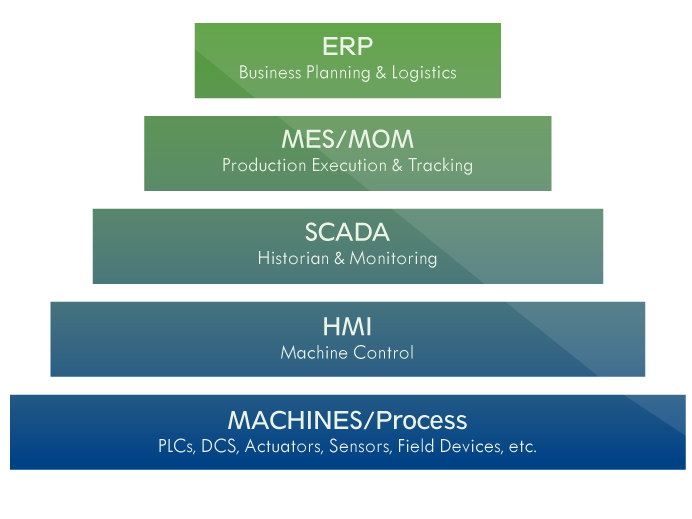

Most manufacturers already have enterprise systems such as Enterprise Resource Planning (ERP), Manufacturing Resource Planning (MRP), or Advanced Planning Systems (APS) to handle customer orders, check inventory, and plan production.

On the other end, control systems—including sensors, push buttons, programmable logic controllers (PLCs), and Human Machine Interfaces (HMIs)—are used to operate machinery. These tools are essential for running equipment but don’t know which product is being made or which materials are being used unless connected to a higher-level system.

Supervisory Control and Data Acquisition (SCADA) systems help bridge this gap slightly by allowing broader monitoring and control across machines or processes. They collect real-time process data, log events and alarms, and are sometimes integrated with HMIs.

But none of these systems manage the full scope of production execution—and that’s the role of MES.

What MES Does

MES is the system responsible for turning production plans into action. It works in real time to:

- Dispatch tasks and guide operators

- Track work-in-progress across lines or facilities

- Record detailed production history

- Enforce procedures and quality standards

- Monitor resource status and availability

Core MES Capabilities Include:

- Detailed resource scheduling and equipment status

- Production task dispatching and sequencing

- Traceability and product genealogy

- Work-in-progress (WIP) and inventory tracking

- Quality enforcement and deviation handling

- Maintenance management

- Work instructions and document control

- Real-time performance analysis and reporting

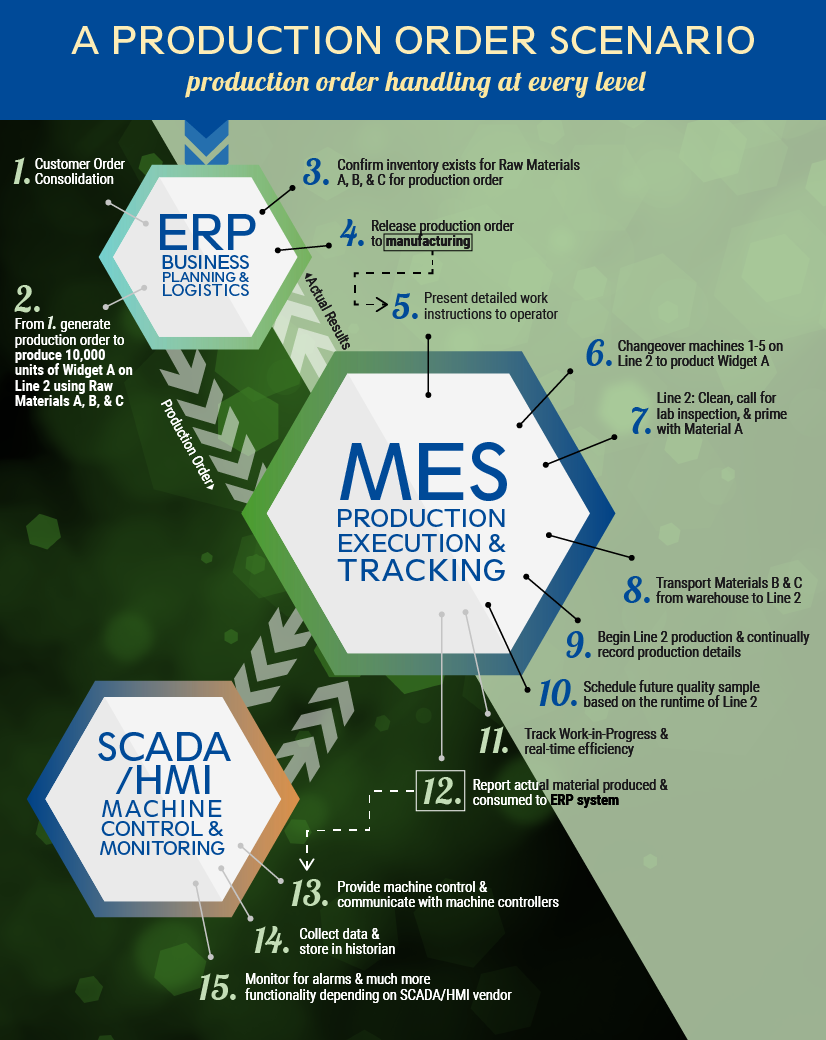

While some of these functions overlap with what ERP or SCADA systems provide, MES operates at a much more granular level. For example, ERP might schedule a product run, but MES ensures that the right operators follow the right steps, that materials are available at the line, and that every step is logged—right down to a machine warm-up or a manual inspection step.

ERP systems are not real-time and are not designed to collect the volume or frequency of data required by MES, SCADA, or HMI systems. In most cases, ERP records high-level information—such as completed production, finished goods, and consumed materials—after the process is complete.

MES, on the other hand, can track production activity down to the second or faster. This enables real-time updates to schedules, work-in-progress, performance metrics, quality checks, and other critical data, rather than waiting until the end of the shift or day.

The image to the left illustrates a typical production order scenario. It highlights the many detailed steps that take place on the plant floor, which are not managed by ERP but are continuously tracked by MES.

ISA-95 Definition

The International Society of Automation (ISA) is an organization that sets standards for the automation industry. One of its key standards is ISA-95, developed by a committee of volunteer industry experts to address the challenges of integrating business systems with manufacturing systems. ISA-95 helps reduce complexity and cost by providing a common language and model for describing how raw materials are transformed into finished goods through tracking, control, and documentation.

Within this framework, ISA-95 uses the term Manufacturing Operations Management (MOM) to define the layer between enterprise-level systems and control systems. It outlines four key areas within this layer: production operations management, maintenance operations management, quality operations management, and inventory operations management.

Excited to learn more? Reach out to us to schedule a live demo today!

Why MES Definitions Vary

The term Manufacturing Execution System (MES) is widely used across the industry, but its exact definition can vary depending on the source. Organizations like the International Society of Automation (ISA) define MES as part of a broader category called Manufacturing Operations Management (MOM) within the ISA-95 standard. MOM includes areas such as production, maintenance, quality, and inventory operations management.

However, the term MES predates ISA-95 and has become more broadly recognized in industry conversations. As a result, many software vendors and analysts use “MES” to describe functionality that goes beyond what ISA includes in MOM. For example, research firms like Gartner, LNS Research, and ARC Advisory Group may include batch systems or other capabilities under the MES umbrella—even if ISA-95 classifies them differently.

Because of this, MES remains the more familiar and widely used term, even if definitions vary slightly across standards and sources.

with real-time operations on the shop floor.