Statistical Process Control

Automatically collect Statistical Process Control (SPC) data, improve quality analysis, and ensure your SPC data is accurately collected on time, every time using the powerful features of our Sepasoft® SPC Module.

Introduction to Statistical Process Control

Introduction to Statistical Process Control

Ensure that statistical process control (SPC) data is accurately collected on time, every time by using the powerful features of the Sepasoft® SPC Module for Ignition®. SPC will help you reduce or eliminate late or missing sample collection, inaccurate sample data, or other issues leading to quality problems. Deliver your SPC data in real-time to the right people in a comprehensive format using the flexible control charts and analysis tools.

Some SPC Module features include:

- Simple Automatic Sample Scheduling

- Quick Automatic Signal Evaluation

- Powerful SPC Control Charts

- Easy Automatic Data Collection

- Unparalleled Collaboration

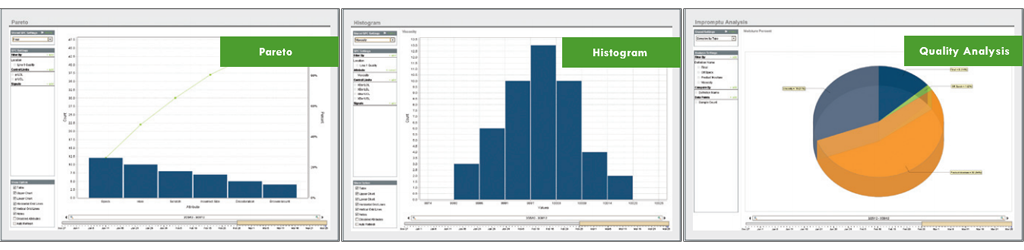

Improve Quality Analysis

Leverage the full power of Sepasoft® MES software to facilitate the collaboration and analysis of quality data across your entire enterprise with the SPC Module. Go beyond typical SPC software offerings with simple automatic sample scheduling, quick automatic signal evaluation, powerful SPC control charting, and easy automatic data collection.

Increase Accuracy & Prevent Late SPC Samples

Taking accurate, regularly-scheduled samples is vital to maintaining quality. That’s why our SPC Module makes it easy to schedule them automatically in real-time. Take samples based on actual production conditions and use convenient, automated alerts to help ensure all are accounted for. Customizing a sampling schedule is simple and flexible, empowering you to meet the requirements of your unique production environment.

Notifications

The Sepasoft® SPC Module is designed to ensure samples are taken on time. A list of upcoming, due, and overdue samples by department or location allows you to quickly view the latest status updates. The system can also automatically send out email and SMS notifications or flash screen indicators to prompt sample taking. You can even set up the system to automatically stop production if a sample is overdue.

The SPC Module can be configured to automatically approve samples or hold them for approval. Whether you want to set up automatic approvals or hold samples for manual sign-off, this module meets your needs. Easily create sample definitions for attributes, control limits, signals, and sampling locations, and choose attributes from variable data types such as real, integer, boolean, and more.

Automatic Alerts for Out-of-Control Conditions

To ensure optimal quality, processes need to be kept within acceptable control limits. Manual intervention should not be required in order to identify out-of-control variations. With Sepasoft’s SPC Module, you will receive an automatic alert if an anomaly is detected. Alerts are easy to customize and can prompt automatic emails, SMS notifications, flashing screen indicators, production stops, and more. Quickly identifying and resolving out-of-control variations prevents small problems from escalating into much larger (and more costly) issues down the line.

Central Server

The SPC Module sends alerts from a facility

Control Limits & Signals

The Sepasoft® SPC Module has typical built-in control limit calculations that can be modified or added onto. While the SPC Module comes with standard signals for your ease of use, you can edit, copy, or create your own when the production environment calls for something more.

Customize Charts

All data requires careful analysis to drive positive action, so we built the SPC Module with a full range of flexible SPC Control Charts. With proper security permissions, you can calculate control limit values and set them interactively. You can also leverage custom data items (i.e. vendors, tooling) in your analysis to associate and visualize other production information alongside SPC data.

With customizable appearance settings for charts, tables, control limits, and signals, you have the power to see the information you need—the way you want it.

Supported Control Charts include:

Easy Updates & Impromptu Analysis Tool

It’s easy to keep information in your SPC Control Charts up-to-date. Simply add notes as samples are taken, and assign causes whenever necessary. The system automatically updates the charts with every new sample, giving you immediate access to the most accurate data when you need it. The SPC Module also includes Impromptu Analysis; a tool that allows users to select unique combinations of data value, filters, groupings, and orders to help you zero in on the cause of quality-related issues.

Connect to Virtually Any Device

SPC data can come from a variety of sources, so our SPC Module comes with the tools you need to collect it. Sepasoft® SPC was built with support for automatically collecting data from PLC devices, OPC-connected devices, lab instruments, RS232 devices, USB devices, data files, web services, and external databases.

PLCs

Connect to any PLC through OPC

USB Devices

Connect SPC data via USB devices

Databases

Connect to any number of databases

Other Devices

Gather data from just about any device

Data Collection

Raw material, vendors, maintenance, humidity, temperature, and much more — it all affects quality. Sepasoft’s SPC Module captures these important — but often overlooked — variables. Our built-in instrument interface module enables data collection from a wide variety of sources, including:

PLC devices, OPC-connected devices, lab instruments, RS232 devices, USB devices, data files, web services, and external databases. Manual and hybrid data entry are supported, as well as offline data collection using mobile iOS or Android devices.

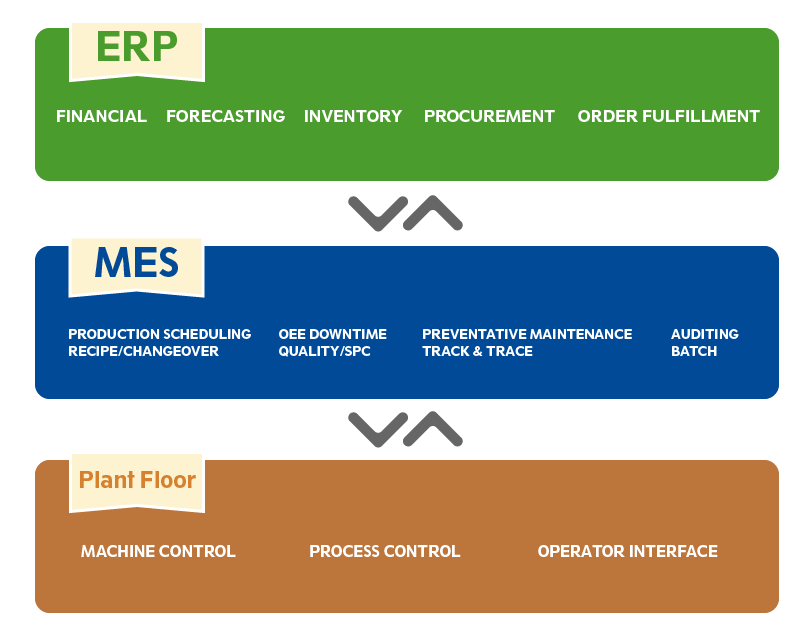

MES Application Collaboration

The Sepasoft SPC Module seamlessly collaborates with the full range of other Sepasoft MES applications. This unified system can collect quality information as well as track OEE (overall equipment effectiveness) and downtime, recipe management, traceability, and more.

As a result, you can reduce double entry and generate more raw data for analysis, reports, and companywide sharing. This collaborative power gives you the ability to cross-reference data, identify trends, look for correlations, and more. In essence, our Sepasoft® SPC Module breaks down the walls between the lab and the plant floor by transforming raw data into useful, actionable information.

The SPC Module seamlessly collaborates with the full range of other Sepasoft MES applications. This unified system can collect quality information, track OEE (overall equipment effectiveness) and downtime, manage recipes, and more.

A fully integrated system reduces the need for double entry and generates reliable data that can be used for analysis, reporting, and companywide sharing. This collaborative power gives you the ability to cross-reference data, identify trends, look for correlations, and more. In essence, the SPC Module breaks down the walls between the lab and the plant floor by transforming raw data into useful, actionable information.

SPC & ERP Integration

Use the Sepasoft® Web Services and database capabilities to easily connect your enterprise resource planning (ERP) systems, MES applications, and plant floor control systems as your central hub.

Because Sepasoft® is cross-platform and based on open standard protocols such as Java, SQL, and OPC-UA, you can connect all your devices, databases, and computers together to achieve unparalleled collaboration.

To learn more or to purchase the SPC Module, contact Sales at 800-207-5506, select Option 1, or visit our pricing page