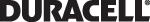

The Sepasoft® MES Suite provides control, traceability, and documentation of the transformation of raw materials into finished goods in real-time.

A manufacturing execution system (MES) is used to control, track, and document the transformation of raw materials into finished goods in real-time. MES systems are capable of tracking production by the second and, in some cases, less than one second.

Control

Track

Document

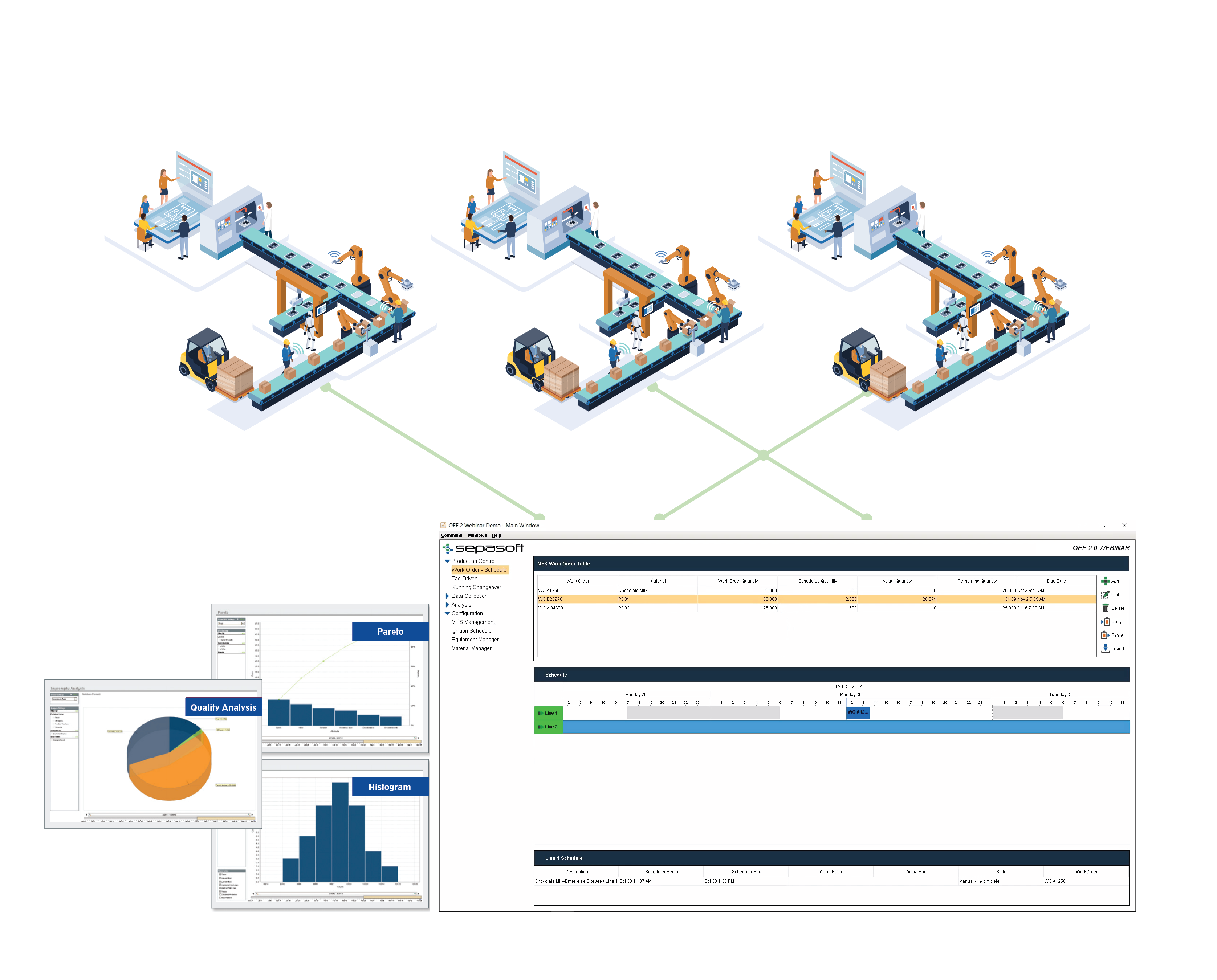

The primary value-added benefits provided by the Sepasoft® MES system include:

• Detailed resource scheduling and statuses

• Dispatching production tasks and sequencing

• Traceability and Genealogy

• Work-in-progress and inventory details

• Ensuring quality

• Work instructions and other document control

• Performance analyses

MES Solutions. Delivered.

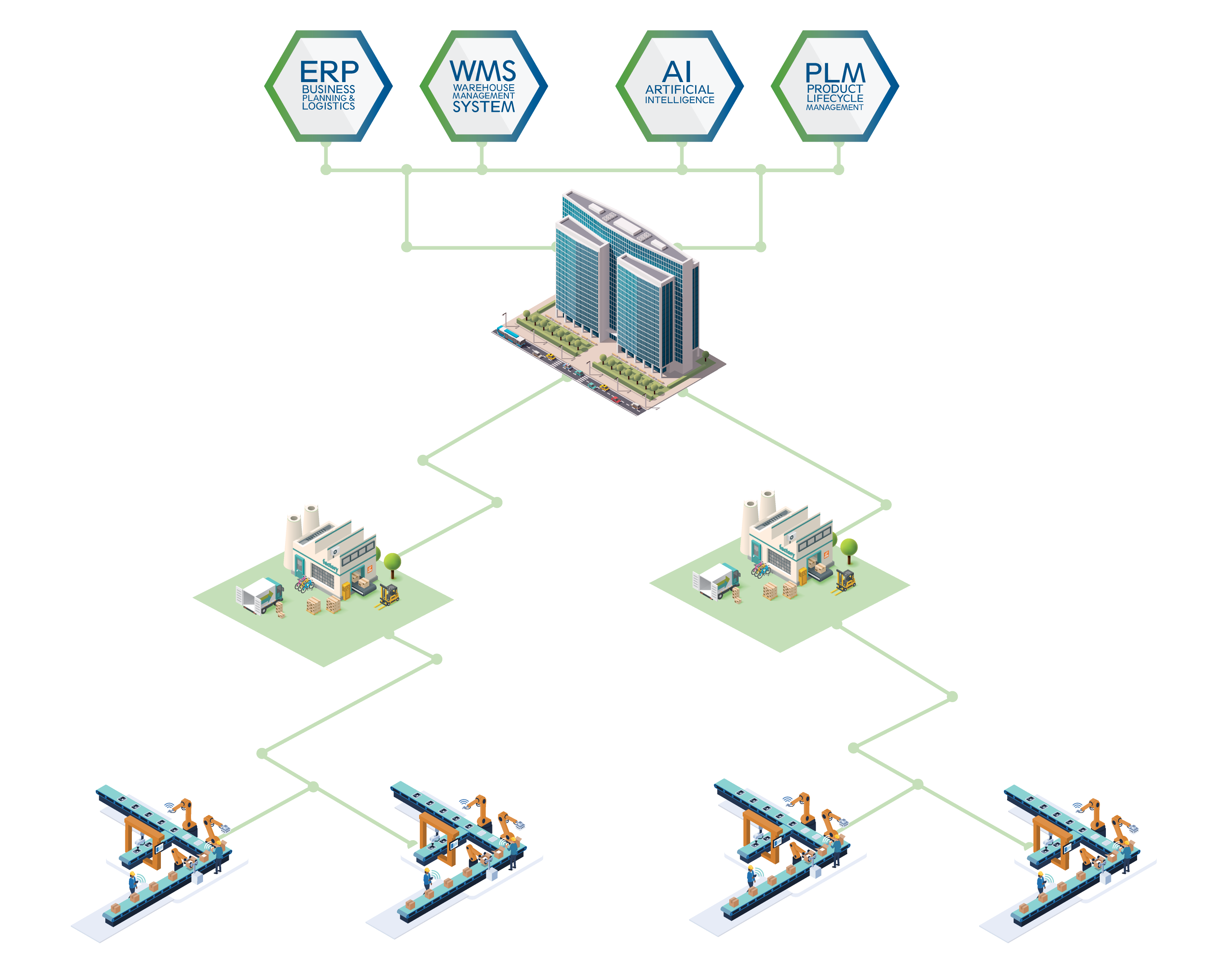

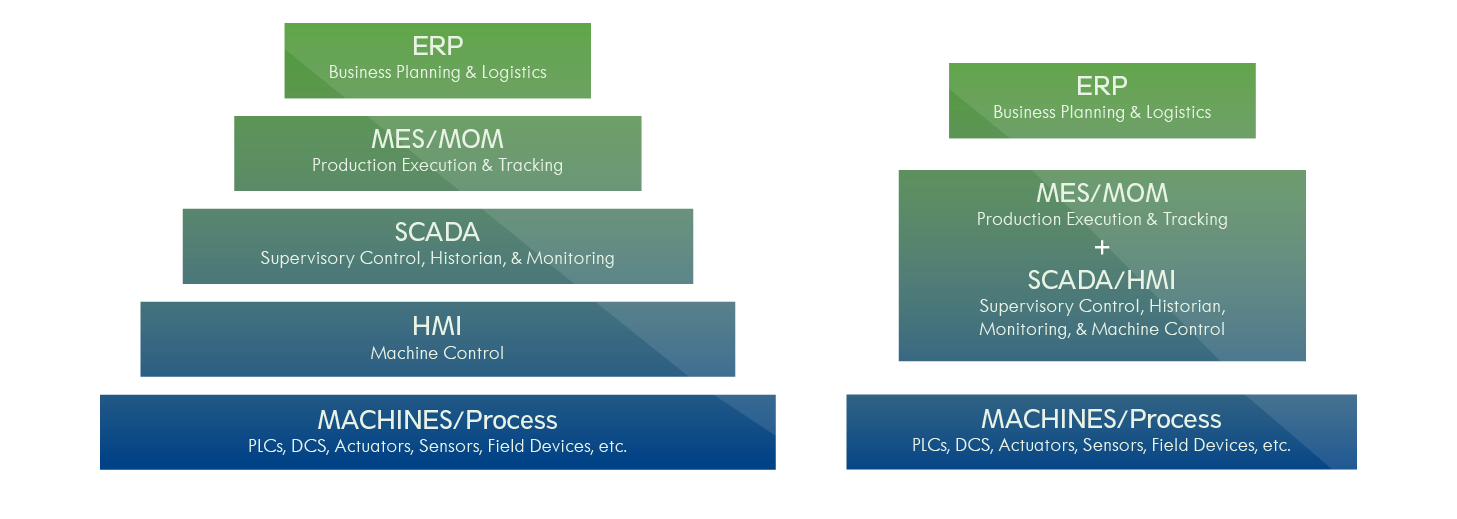

Sepasoft® MES is scalable from a single site to full scaled global enterprise MES solutions. Scroll through the images below to see the possible architectures.

Optimize a single site or span your global enterprise, featuring:

• Optimized rollout process to benefit from quicker returns on investment

• Out-of-box synchronization of production data across MES servers

• A flexible MES solution tied in with your ERP system

• Efficiently communicate production data seamlessly across your enterprise

• Flatter User Interface Stack reducing implementation and training costs

• Built on the Ignition® Platform, by Inductive Automation

• Simplified update procedures reduce IT expenses and TCO

• Unlimited licensing, tags, and clients

• An affordable solution

Our MES Solutions Provide You Real Tools for Your Digital Transformation.

Sepasoft® MES Solutions Solve the Challenges with Controlling, Tracking, and Documenting the Transformation of Raw Materials into Finished Goods, in Real-Time.

Save Money

• Maximize your Production Efficiency

• Reduce Production Downtime

• Eliminate Material Rework/Scrap

• Monitor High-Level View of Production

• Lower OT/IT Costs

• Increase Asset Utilization

Save Time

• Enterprise-Wide Production Data Sync

• Global Enterprise Connectivity

• Easy Project Customization

• Track Production Data Trends Digitally

• Manage Your Inventory in Real-Time

![]()

Increase Flexibility

• Customize to Your Production Environment

• Plant Floor to Business System Connectivity

• Real Time Data Acquisition,

• Real Time Sampling, & Monitoring…

• …Accessible Onsite or Remotely

Flexibility Knows No Bounds.

Our MES Solutions Deliver the Utmost in Efficiency While Remaining Flexible and Fully Customizable, Suited For Your Needs.

Plant Floor Operations Have Never Been Easier, Featuring:

• Synchronized Production Data

• Realtime Digital Plant Floor Management

• Centrally Accessible Digital Production Data

Flatten-the-Stack.

Save Hours of Customization with Optimized Stack Layering and Reduce the Impact on Operations Staff with a Unified Operator Interface.

MES/MOM & HMI/SCADA Layers Use the Same Client & Designer, Featuring:

• A Single Interface for Operations, with Interlocks

• 1+ Designer & Client, All Managed by a Single Platform

Excited to learn more? Reach out to us and schedule your live demo today!